BB420 is built to withstand the toughest of environments, without compromising on design or comfort. The BB420 beam seat range stands up to heavy use while having a clean and simple aesthetic. Flexible PU seating offers comfort for short and long term sitting, while a robust die cast frame and components gives strength without compromising function.

- Antimicrobial surface

The BB420 is designed specifically for high traffic areas using materials proven to last. The antimicrobial surface inhibits microorganism growth, to minimising the spread of contaminates by keeping a germ-free space. Pared back detail means it’s very easy to clean – making it ideal for larher seating facilities.

2. Flexible PU material

Created using high quality moulds, the BB420 has a fully moulded PU seat available in 12 standard colours, or can be manufactured to match any Pantone colour (minimum quantities apply). Despite its hardwearing nature, the PU also provides some softness and warmth to the touch, with a flexible feel for extra comfort. The PU seat and back have a steel inner frame, supported by a cold rolled mild steel beam and pressure diecast aluminium legs and arms.

3. Customisable components

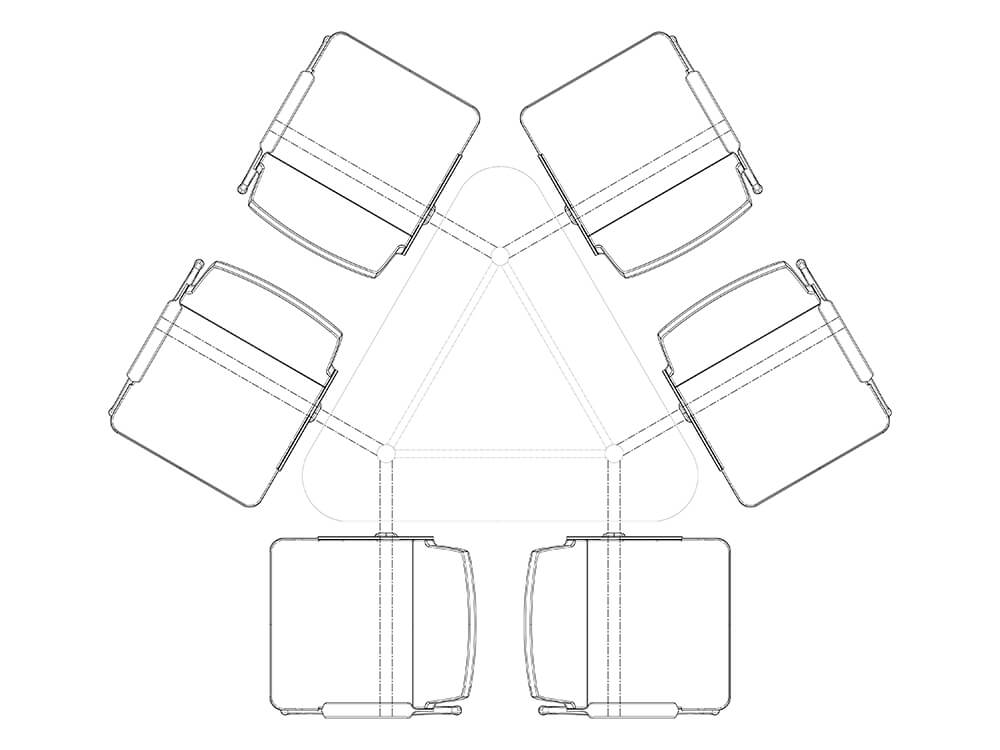

Define your space with the option of no arms, end arms only or intermediate arms. Arrange in continuous rows, back-to-back, floor fixed or freestanding. Configurations are limitless, like the BB420 Pod – available with built in tables and power facilities. Printing on PU is an option, to create designated seating zones for patients with reduced mobility.

4. Certified

BB420 has been tested to BS EN 12727:2016 which includes safety, strength. durability and fire retardant materials. Each seat holds a maximum capacity of 150kg.

Looking for a medical beam seat? Contact us today